1. The difference between DC and AC motors

DC motors use direct current as a power source, the AC motor uses AC as a power source.

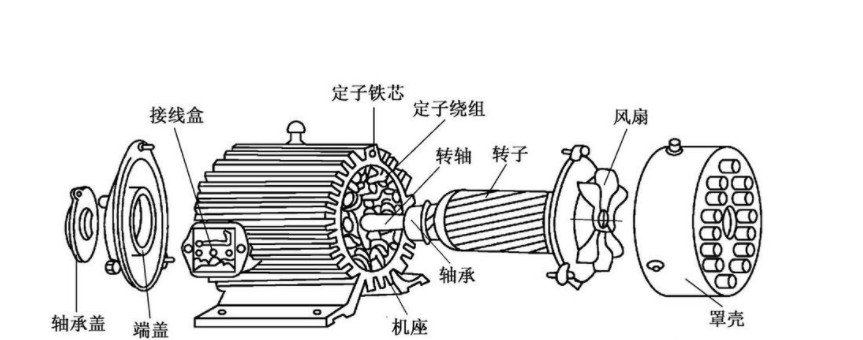

①From the structural point of view, the principle of the DC motor is relatively simple, but the structure is complicated and not easy to maintain.

The AC motor has a complex principle but relatively simple structure, and is easier to maintain than a DC motor.

②In terms of price, DC motors with the same power are higher than AC motors.

Including the speed regulating device that controls the speed, the price of DC is higher than that of AC. Of course, the structure and maintenance are also very different.

③In terms of performance, due to the stable speed and precise speed control of the DC motor, which cannot be achieved by the AC motor, the DC motor has to be used instead of the AC motor under the strict requirements of the speed.

AC motor speed regulation is relatively complicated, but it is widely used because of the use of AC power in chemical plants.

2. The difference between synchronous and asynchronous motors

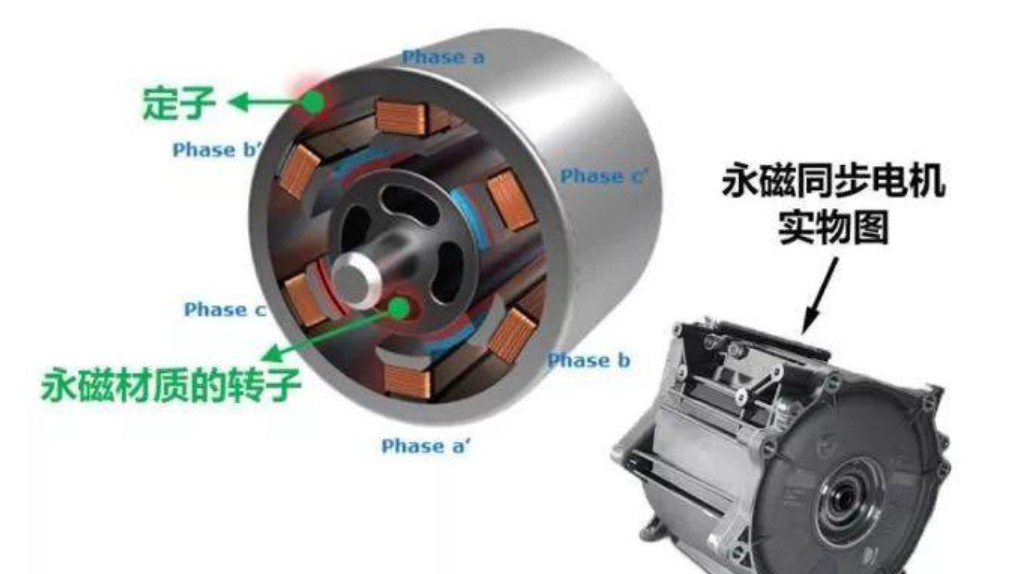

The rotation speed of the rotor is the same as that of the stator, which is called a synchronous motor.

If inconsistent, it is called asynchronous motor

3. The difference between ordinary and variable frequency motors

First of all, it is clear that ordinary motors cannot be used as variable frequency motors.

Ordinary motors are designed according to constant frequency and constant voltage, which cannot fully meet the requirements of frequency converter speed regulation, so they cannot be used as variable frequency motors.

The frequency converter can generate different levels of harmonic voltage and current during operation, so that the motor runs under non-sinusoidal voltage and current. The high-order harmonics inside will cause the motor stator copper loss, rotor copper loss, iron loss and additional loss.

Among them, the most significant is the copper loss of the rotor. These losses will cause the motor to generate additional heat, reduce the efficiency, and reduce the output power. The temperature rise of ordinary motors generally increases by 10%-20%.

The carrier frequency of the frequency converter is from several kilohertz to ten kilohertz, so that the motor stator winding has to withstand a high rate of voltage rise, which is equivalent to imposing a steep impulse voltage on the motor, which makes the inter-turn insulation of the motor bear more.

When an ordinary motor is powered by a frequency converter, the vibration and noise caused by electromagnetic, mechanical, ventilation and other factors will become more complicated.

The various harmonics contained in the variable frequency power supply interfere with the inherent spatial harmonics of the electromagnetic part of the motor to form various electromagnetic excitation forces, thereby increasing noise.

Due to the wide range of the working frequency of the motor and the wide range of rotation speed, the frequency of various electromagnetic force waves is difficult to avoid the natural vibration frequency of the various structural parts of the motor.

When the frequency of the power supply is low, the loss caused by the high-order harmonics in the power supply is large; secondly, when the speed of the flexible motor is reduced, the cooling air volume decreases in proportion to the third power of the speed, so that the motor heat cannot be dissipated, and the temperature rises sharply. It is difficult to achieve constant torque output.

Reported by Jessica

Contact: John

Phone: +86-13631626001

E-mail: support@szbobet.com

Add: Longhua Area,Shenzhen City,China